A SEESUO Patch Cord can be used in a high density environment. Comparing to the conventional duplex connector, the design is more compact, as well as just one cable was used, which help to improve the hot air flow in a high density and a crowed environment.HYC did an unique and a patented design to reach in a highest density in the industry.

How To Choose OPTICO's Fiber Patchcords?

As one of the most basic components of optical network cabling, fiber optic patch cords are widely used in the construction of fiber optic links. Nowadays, fiber optic manufacturers launch many types of fiber optic patch cords according to different application scenarios, such as MPO/LC/SC/FC/ST/MTRJ/MU/E2000/DIN fiber optic patch cords, simplex/duplex fiber optic patch cords, singlemode/multimode fiber optic patch cords, etc., which have their own characteristics and are irreplaceable. optico produces a wide range of indoor and outdoor high quality fiber optic patch cords. The following helps you quickly identify and locate the fiber optic patch cords you you need.

Classification Of Fiber Optic Patch Cords

Although these different types of fiber optic patch cords have similar components (consisting of connectors and fiber optic cables) and the same functionality, there is variability in application scenarios due to the different characteristics and performance between them.

Different Fiber Cable Composition Structure

Fiber optic patch cords can be divided into ribbon fiber optic patch cords and bundled fiber optic patch cords according to the different composition structure. Ribbon fiber optic patch cord is used by the fiber optic tape composed of ribbon fiber optic cable, mostly flat shape, because of the high fiber density, it can accommodate more cores, so greatly save cabling costs and space, while the bundle fiber optic patch cord is used in bundled fiber optic cables, which is usually composed of 0.9mm loose casing or loose set of fibers, most of them are round, mainly used for indoor integrated wiring.

Different Applications Scenes

According to the different application environments, fiber optic patch cords are divided into conventional fiber optic patch cords and reinforced fiber optic patch cords. Conventional fiber optic patch cords are characterized by lighter weight and lower cost, which can meet the use of most indoor transmission equipment and data center high-density cabling needs, so the conventional fiber optic patch cords are also more commonly used in daily life. Reinforced fiber optic patch cords are generally used in underground tunnels, base station construction and other harsh outdoor environments, so they usually need to have the ability to prevent insects and rodents from biting, waterproofing and high temperature resistance to avoid damage, affecting normal communications. In order to cope with the harsh environment, people according to the use of scenarios designed and developed different types of reinforced fiber optic patch cords, such as armored fiber optic patch cords, military-grade field fiber optic patch cords, IP67 waterproof fiber optic patch cords reinforced fiber optic patch cords, such as armored fiber optic patch cords, military-grade field fiber optic patch cords, waterproof fiber optic patch cords with IP67 waterproof fiber optic patch cords, as well as the FTTA pull distance patch cords and so on.

Different Polishing Angle

According to the different types of fiber optic connector polishing, fiber optic patch cords are divided into three types: PC, UPC and APC. PC fiber optic patch cord adopts micro-spherical grinding and polishing of connectors with black color; APC fiber optic patch cord adopts 8° beveled grinding and polishing of connectors with green color; UPC fiber optic patch cord optimizes the end face polishing and surface finish on the basis of PC fiber optic patch cord, with blue color. There are differences in the structure and performance of the three polishing methods of fiber optic patch cords, which are mainly reflected in the insertion loss and return loss. Among them, APC is the most popular polishing type at present.

Different Fiber Cores Count

According to the number of fiber cores, fiber optic patch cords can be divided into simplex (single core) fiber optic patch cords and duplex (dual core) fiber optic patch cords.

Different Tansmission Mode

According to the different optical transmission modes, fiber optic patch cords are divided into single-mode fiber optic patch cords and multi-mode fiber optic patch cords. Single-mode fiber optic patch cord can only transmit a mode of light, inter-mode dispersion is small, suitable for long-distance communication, while multi-mode fiber optic patch cord can transmit multi-mode mode of light at a time, inter-mode dispersion is large, and with the growth of the transmission distance, the inter-mode dispersion intensifies, so it is more suitable for short-distance transmission.

Different Outer Sheath Material

PVC and LSZH are the commonly used jacket materials for fiber optic patch cords.PVC fiber optic patch cords are more pliable and flexible when installed at normal temperatures, and are usually used indoors, such as in the laying of horizontal sub-wiring systems. Compared with PVC patch cords, LSZH (Low Smoke and Halogen Free) fiber optic patch cords contain flame retardant compounds that do not release toxic fumes when burned, and are commonly used in unventilated areas exposed to public places such as subways and tunnels.

High Reliability And Stability

The reliability and stability of patch cords are crucial to the stability of data transmission, so OPTICO chooses CCTC high-quality ceramic inserts, YOFC/Corning and other big-name fiber cores, as well as high-quality brand-new sheath materials to produce a variety of patch cords.

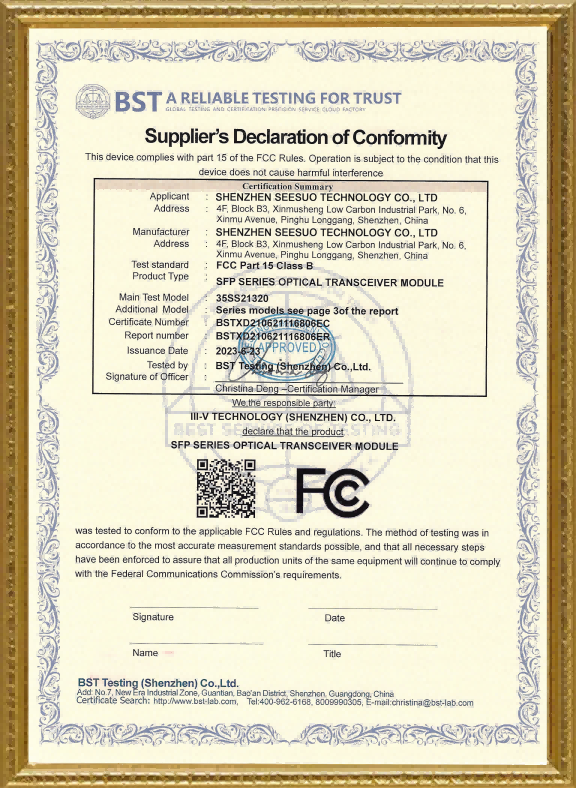

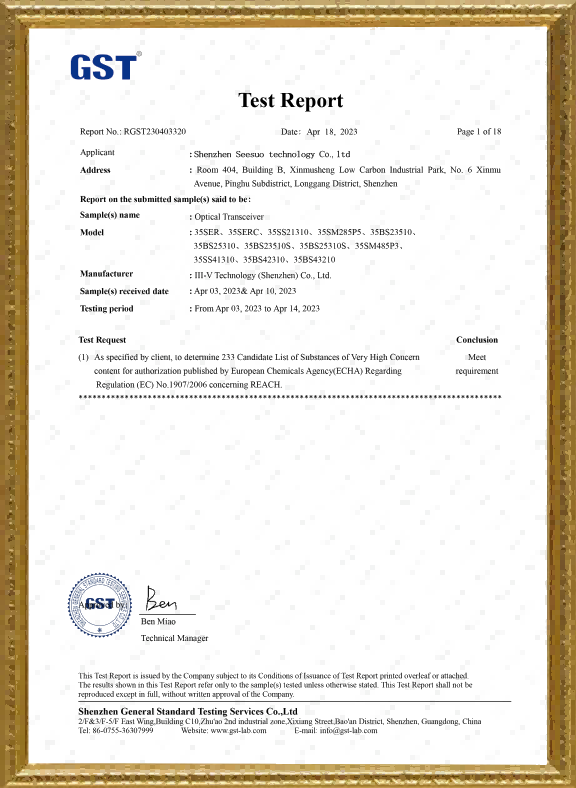

So far, its stability data has been fully certified by the third-party laboratory CTI.

Standard Fiber Optic Patch Cable Series

9/125μm OS2 single mode and bend-insensitive SEESUO Fiber Optic Patch cables have less attenuation when twisted compared to conventional fiber optic cables, making these fiber optic cables more efficient to install and maintain. It also saves more space for your high density cables in data centers, corporate networks, telecom pop points, server rooms, cloud storage networks and where Fiber Patch cables are required.

The SEESUO series Fiber Optic Patch cables are specifically designed to cater to 1G/10G/25G/40G/100G/400G Ethernet connections. These cables offer reliable data transmission capabilities, enabling data to be carried up to 10 km at 1310 nm or 40 km at 1550 nm.

Bend Insensitive, Ultra Low Loss Patch Cable Series

The SEESUO series Fiber Optic Patch cables feature bend-insensitive G657 A2 fiber optic technology, allowing for a tight bend radius of 7.5mm. These cables are produced in accordance with international standards and exhibit low insertion loss (IL) values, ensuring reliable data transfer over long distances. >With IL values exceeding 97% for an average of ≤0.12dB and a maximum of ≤0.25dB, these cables meet the demands of state-of-the-art wide bandwidth and high-speed applications. They enable the transmission of large data streams efficiently and effectively.

-

Single Mode and Muti Mode Options

-

Insertion Loss (IL) ≤0.2dB

Uniboot Fiber Patch Cable Series

The SEESUO Patch Cord Armored Series includes internally metal armored fiber optic patch cables. These cables provide stronger external protection compared to standard fiber optic cables. They are designed with a solid armor layer, allowing them to be installed in hazardous areas with light dust, oil, gas, moisture, and potential damage from rodents and vermin. With a tensile strength ranging from 225N to 320N, they offer reliable durability. The Armored Series is available in both Duplex and Simplex configurations.

Armored Fiber Patch Cable Series

The SEESUO Patch Cord Armored Series includes internally metal armored fiber optic patch cables. These cables provide stronger external protection compared to standard fiber optic cables. They are designed with a solid armor layer, allowing them to be installed in hazardous areas with light dust, oil, gas, moisture, and potential damage from rodents and vermin. With a tensile strength ranging from 225N to 320N, they offer reliable durability. The Armored Series is available in both Duplex and Simplex configurations.

SEESUO FIBER OPTICTEST CAPACITY

All of our products are tested by our experienced engineers at international standards with state-of-the-art testing equipment.

Classification of the application of fiber patch cords

Fiber patch cords are generally divided into MTP/MPO fiber patch cords, conventional fiber patch cords, armored fiber patch cords, etc.

1. MTP/MPO fiber patch cords: Commonly used in fiber optic line environments that require high-density integration in the wiring process. Its advantage is that it uses a simple push-pull locking structure, which is easy to install and remove, saves time and cost, and maximizes service life.

2. Armored fiber patch cords: Commonly found in computer rooms, suitable for harsh environments. Its advantages are that it does not need to use a protective sleeve, it can prevent moisture and fire, it has antistatic properties and acid and alkali resistance, it can save space and reduce construction costs.

3. Conventional fiber patch cords: conventional fiber patch cords include OS2 9/125 single mode simplex, OM4 40/100Gb 50/125 multimode, OM3 10Gb 50/125 multimode, OM2 50/125 multimode, OM1 62.5/125 multimode , OS2 9/125 single-mode simplex, OM5 50/125 multi-mode these types. Among them, OM5 fiber patch cord is the most popular product at present. It is often used in the application of higher broadband. The outer sheath is aqua green. It has strong scalability, compatibility and interoperability, and can effectively reduce costs.

Main Raw Materials of Our Patch Cord

We adopt finest materials for brilliant performance, to ensure the products you get in the low IL, great uniformity, less bubble, small concentricity and aperture.

All the materials are ROHS certificated and meet exporting quality level demand.

These are our principle and basement to have a good reputation of quality in the FTTH area.

-

Ferrul:CCTC

-

Fiber: YOFC, Corning, FiberHome, Zhongzhu

-

Kits:InforeMaterial uses plastic and zinc alloy.

FAQ:

Q:Can I use these cables underground with?

A:No. Instead, you can examine our Industrial or CPRI Patch Cable series.

Q:What is the minimum pressure (compression) strength of the armored cable?

A:Minimum compression strength is 2000N/10CM (Long term) or short term compression strength is 3000N/10CM.

Uses of Fiber Optic Patch Cords

Fiber optic patch cords have many uses in almost every industry. Some of the benefits are:

-

Fiber optic patch cords help connect network devices with serial connections and allow easy changes to network layouts without punch blocks or patch panels.

-

Fiber optic patch cords connect computer systems, monitors, printers, and data storage devices to networks.

-

They’re also valuable for connecting audio equipment like speakers, microphones, and mixers.

-

Fiber optic patch cords are often helpful when replacing them and are more convenient or less expensive than repairing damaged connectors on equipment.

Precautions for the Use of Fiber Optic Patch Cords

Notes on the use of fiber optic patch cords: (including single-mode fiber optic patch cords and multimode fiber optic patch cords):

-

Optical transceiver modules wavelength matching: Optical transceiver modules wavelength matching at both ends of the fiber optic patch cords. The most common differentiation technique is to compare the color of the fiber optic patch cords.

-

Unless stated otherwise. Orange multimode fiber is used in the short-wave optical module. Yellow single-mode fiber is used in the long-wave module. This is a common misconception because it depends on the manufacturer’s configuration. This is done to ensure data transfer correctness.

-

Since fiber optic patch cords are made of sensitive materials, they should not be bent or wrapped excessively during use. Pay attention to the protective cover, even if it is present. It is not only easy to destroy but will also enhance the amount of light transmitted. Attenuation is a term used to describe reducing the intensity of.

-

Fiber optic patch cords protection: The optical fiber coupling will be damaged if it is not dust- and oil-proof after it has been connected.

Why Choose Us

With over 20 years of experience in optical fiber patch cord production. Fibconet offers products that comply with TIA 604 (FOCIS), IEC 61754, and YD/T industry standards

Each patch cord undergoing 100% rigorous testing.

We offer fiber patchcords conforming to OS2, OM1, OM2, OM3, OM4, and OM5 standards, meeting the application requirements of Gigabit Ethernet, 10 GigabitEthernet and high-speed Fibre Channel.

Contact usfor the latest quotation for those products!

Single mode fiber patch cords: Low insertion loss UPC/APC≤0.3dB, high return loss UPC≥50dB, APC≥55dB; Multimode Optical fiber jumpers: Low insertion loss UPC≤0.3dB, high return loss UPC≥50dB

High quality zirconia ferrules.

Make high-speed ethernet network equipment connections

Excellent in repeatability and exchangeability

High temperature stability

Every cable assembly is 100% tested and guaranteed to meet all specification

High and low temperature -45- + 80 degrees

Customer Lengths and connectors are available upon request

Datacenter Networks between fiber optical transceivers and switches

Optical fiber CATV

FTTX solutions

Fiber optical access and distributional networks

Local area network

Telecommunication transmission

Test equipment

Optical fiber distribution frame (ODF)

| Product Model | Fiber Counts | Fiber Type | Connectors | End Face | Diameter | Length | Outer Jacket |

|---|---|---|---|---|---|---|---|

| SS-1D-SF-AU-20P-3 | 1 | G652D | SC-FC | APC-UPC | 2.0mm | 3m | PVC |

| SS-1D-FF-AU-20P-5 | 1 | G652D | FC-FC | APC-UPC | 2.0mm | 7m | PVC |

| SS-1D-SS-AA-20P-10 | 1 | G652D | SC-SC | APC-UPC | 2.0mm | 10m | PVC |

| SS-1D-SS-UU-30L-5 | 1 | G652D | SC-SC | UPC-UPC | 3.0mm | 5m | LSZH |

| SS-1D-LF-UU-30L-15 | 1 | G652D | LC-FC | UPC-UPC | 3.0mm | 15m | LSZH |

| SS-1A-SS-AU-20P-1 | 1 | G657A1 | SC-SC | APC-UPC | 2.0mm | 1m | PVC |

| SS-2A1-LL-UU-20P-3 | 2 | G657A1 | LC-LC | UPC-UPC | 2.0mm | 3m | PVC |

| SS-2M2-LL-UU-20P-3 | 2 | OM2 | LC-LC | UPC-UPC | 2.0mm | 3m | PVC |

| SS-2M3-LL-UU-20P-3 | 2 | OM3 | LC-LC | UPC-UPC | 2.0mm | 3m | PVC |

| SS-2M4-LL-UU-20P-5 | 2 | OM4 | LC-LC | UPC-UPC | 2.0mm | 5m | PVC |

OEM Manufacturer

SEESUO provides tailored OEM products based on clients' designs and specs.

ODM Manufacturer

SEESUO boastis rich R&D experence and top-notch production management.

Customized production

SEESUO provides talored product design,development, and flexible manufacturing.

R&D cooperation

SEESUO adapts swifly to market changes collaborating with customers in R&D.

What is acceptable db loss for single mode fiber?

What is difference between multimode and single mode fiber?

What is the main difference in performance between OM1 and OM2 Multimode Fiber Patch Cord Cables?

4.9

Ahmad FaizalMalaysia

Ahmad FaizalMalaysia 4.9Using this OS2 duplex on my Huawei CloudEngine 12800 for redundancy. Love the quality, and the 9/125μm fiber handles everything smoothly!

4.9Using this OS2 duplex on my Huawei CloudEngine 12800 for redundancy. Love the quality, and the 9/125μm fiber handles everything smoothly!

Daniela RojasColombia

Daniela RojasColombia 4.8This OM3 patch cord is perfect for my 10G Mellanox SX1012 switch. Excellent performance for high-speed links—totally hassle-free!

4.8This OM3 patch cord is perfect for my 10G Mellanox SX1012 switch. Excellent performance for high-speed links—totally hassle-free!

Akosua AsareGhana

Akosua AsareGhana 4.9Using this OM4 patch cord with my Cisco Nexus 9000 for 40G connections—fast, stable, and perfect for high-bandwidth workloads!

4.9Using this OM4 patch cord with my Cisco Nexus 9000 for 40G connections—fast, stable, and perfect for high-bandwidth workloads!

Online consultation

Online consultation Send email

Send email